Tomorrow’s Powerhouse: Breaking Down the Latest in Deep Cycle Battery Tech

Deep cycle batteries are the core of the transition to renewable energy and more efficient power management systems. As the need for high performance and reliable energy storage solutions grows, battery storage manufacturers are putting more effort into making these powerhouses better by increasing the technology behind them. This article focuses on the newest developments in deep cycle battery technology, showing that the innovations are preparing a more sustainable and energy-efficient future.

Innovations

The heart of the deep cycle battery technology development is the advancement in battery chemistry. The battery storage manufacturers are coming up with new formulations that have high energy density and efficiency. These developments not only prolong the life of the batteries but also provide them with a larger capacity to hold a charge for a longer period, thus enhancing their efficiency. Through the development of lithium-based and other alternative chemistries, manufacturers are extending the capabilities of deep cycle batteries beyond the current limits.

Enhanced Battery Management Systems

The Battery Management System (BMS) is a vital part of a modern deep cycle battery. Nowadays, the BMS technologies are more developed than ever, and they are enriched with intelligent algorithms that improve the charging and discharging processes to extend battery life. Battery storage manufacturers are incorporating these systems to ensure that batteries operate at the best performance, which reduces wear and tear and common issues, which have shortened battery life spans in the past.

Durability and Reliability

Durability and reliability are the key points in deep cycle battery design especially for solar energy storage, electric vehicles, and backup power systems. The developments from deep cycle battery manufacturers are now geared towards making batteries more durable and capable of standing up to the most extreme conditions. It covers both the structural design of batteries and the utilization of more corrosion and damage resistant materials that are less prone to environmental factors.

Advancements

The method of deep cycle battery manufacturing has a major effect on the quality and performance of the batteries. The latest developments in the manufacturing technologies have allowed battery storage producers to manufacture the batteries which are not only of the same quality but also eco-friendly. The modern manufacturing methods are waste-reducing and have low carbon footprint in the battery production. Moreover, deep cycle battery factories have been implementing stricter quality control measures, so that every single unit that is released meets the highest standards.

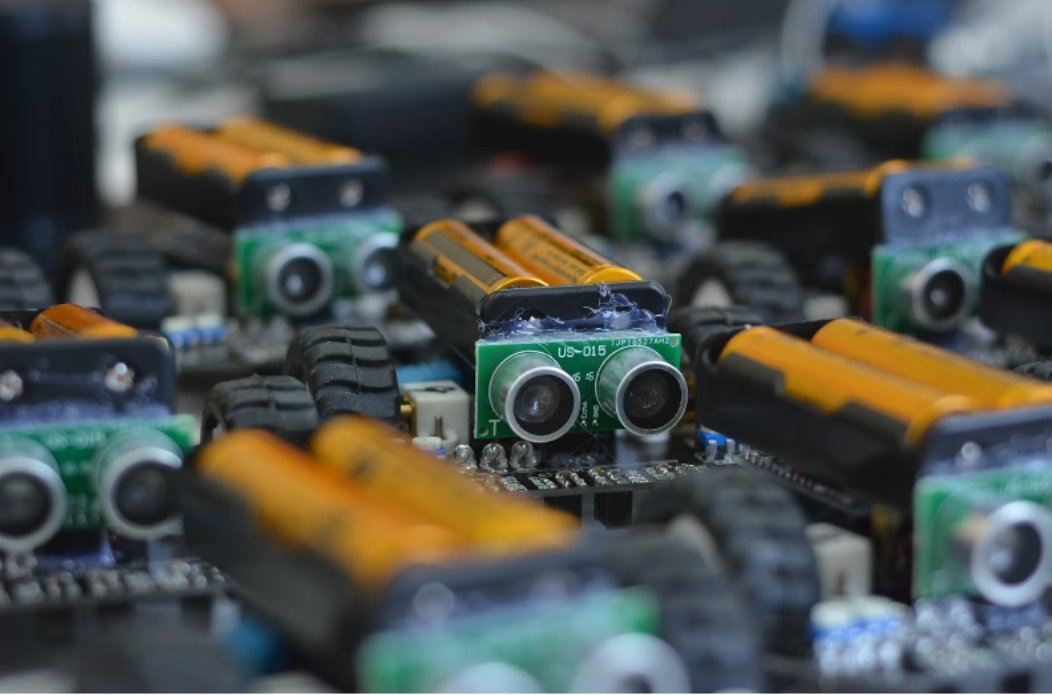

Automation in Production

Deep cycle batteries production involves automation as a key factor. It helps to improve the accuracy and efficiency of the assembly process, which translates to better product consistency and lower production costs. Through the use of automation in manufacturing, battery storage producers can manage the increasing demand and still maintain high quality of the product. Automation in addition to the ability of scaling production, adapting to changes in market demand or technology progress, is another factor.

Finally, the future of deep cycle batteries is bright, as the battery storage manufacturers are consistently making new innovations which are improving technology. As technology is developing, deep cycle batteries will play an increasingly important role in global energy strategies, which will make them the real powerhouses of tomorrow’s energy landscape.

Leave a Reply